복합재료용 장비

10

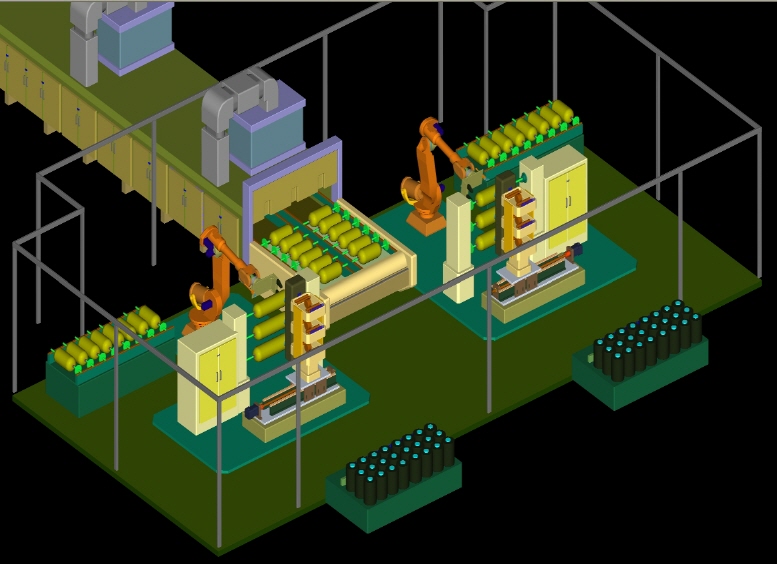

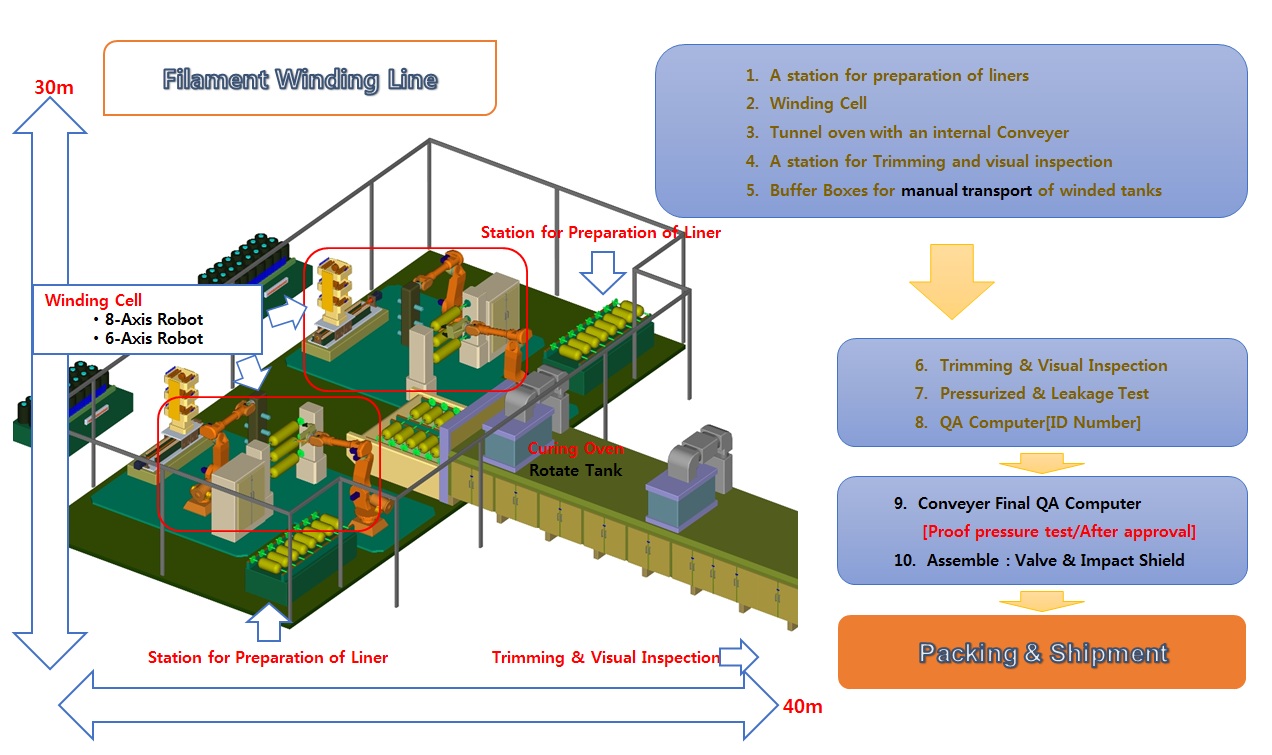

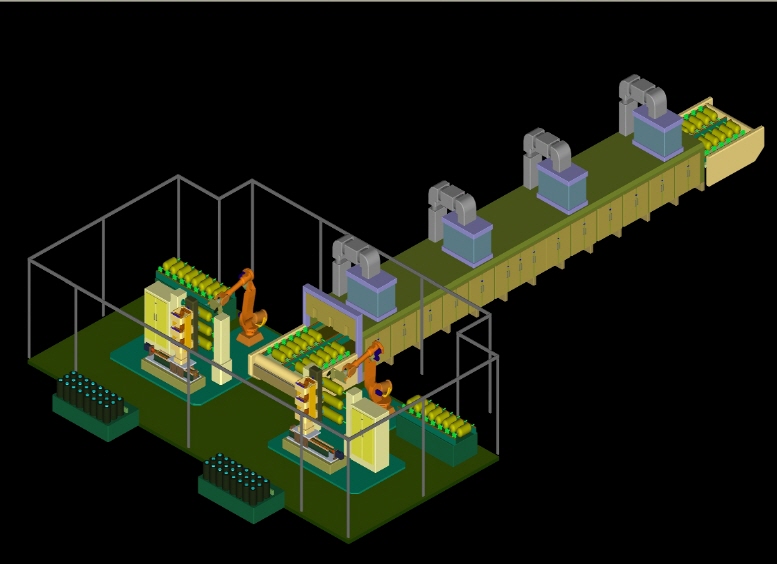

LPG,CNG,수소용기 압력용기 자동화 생산라인

기존의 필라멘트 와인딩 방식에서 탈피하여 로봇을 이용한 와인딩 방식.

와인딩 속도를 현저히 증가시켜 생산 효율을 높이며, 보다 정교한 와인딩 구현이 가능하다는 것이 큰 장점.

와인딩 속도를 현저히 증가시켜 생산 효율을 높이며, 보다 정교한 와인딩 구현이 가능하다는 것이 큰 장점.

- 특징 및 효과

-

- 1. Products : Type 4 cylinders for CNG for use as fuel tanks.

- 2. Dimensions of the products: All products are cylindrical. The maximum length of the products is 1500 mm and the maximum diameter is 410 mm.

- 3. Capacity (32liter cylinder): Capacity at 100% is 36 cylinder/hour, 24 hour x 365 days. The estimated utilization is set to 76%. This gives a maximum annual capacity for 32 liter cylinders of 240 000 cylinders at a 24/7 production the year around.

- 4. Maximum number of roving is 20 per spindle.

- 5. The Production line is prepared for 32 liter cylinder if not otherwise agreed before order. Shafts for the 32 liter cylinder and flaming ring 232mm ± 10mm for the 32 liter diameters of liner.

- Assembly of bushing on liners

-

- Manual assembly of bushing on liners.

- Manual assembly of liner on shaft

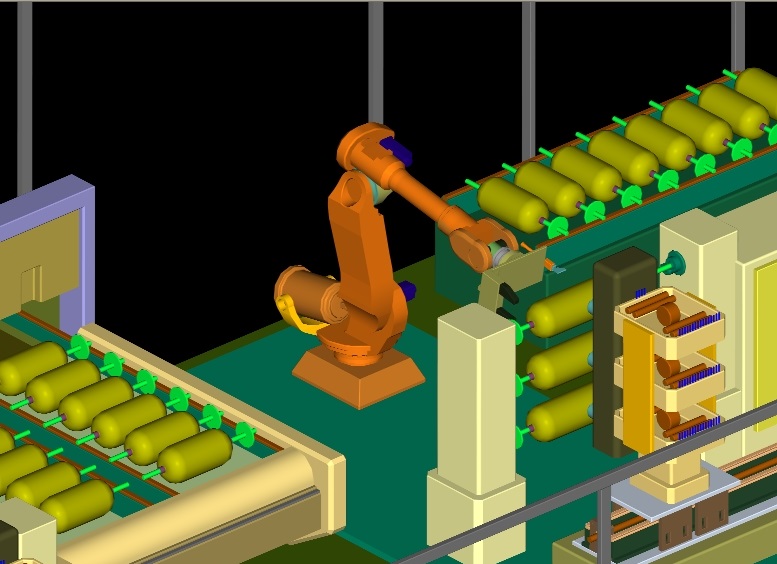

- Preparation of liners

-

- Manual assembly of liner on shaft

- Filling of air to low pressure for handling approx. 0,5bar

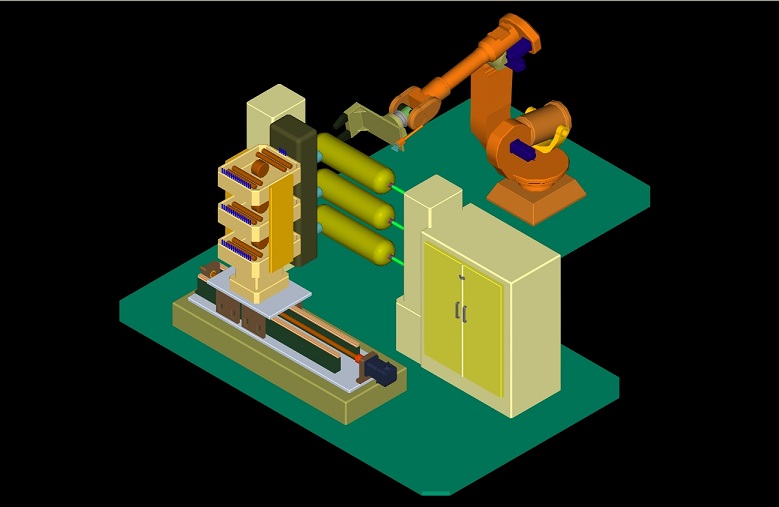

- Winding cell

-

- containing 3 robots, two are winding robots, one is a handling robot

- Model : ABB IRB 6700 M2004

- flaming, pumps

- mixer of resin

- resin bath

- guiding for roving

- Oven

-

- tunnel type

- convection electrically heating system

- Proof test

-

- 1-4 cylinders are tested simultaneously in proof test box with water. (300bar)

- Fatigue test

-

- 1-3 cylinder are tested simultaneously in each burst chamber

- Burst test

-

- 1 cylinder at a time is tested in a burst chamber

- Leakage test

-

- cylinders are tested simultaneously with compressed air (200bar)

- 장비사진

-

- 장비사진

-

- 장비사진

-

- 장비사진

-