Automatic Machinery

Composite Equipment

5

3D Rectangular Braiding Machine for advanced composite preform

In the 4-step braiding method, each machine cycle involves four different motions in order to intertwine the longitudinal yarns that are positioned in row and column directions along the cross-section. Braider yarns, on the other hand, are intertwined by braider carriers that move in predetermined paths within the matrix so as to form the fabric. 3D braided preform has a layered structure. Yarns are intertwined with each other according to a certain path and are biased such that the width of the fabric is at an angle between 10˚and 70˚. The process involves rectangular layout of individual row/column arrangements in the machine bed. Each individual row has a braider carrier in order to carry out four different cartesian motions.

Three dimensional(3D) braided composites were recognized as the most promising materials because of their low delamination tendency. Furthermore, the near-net-shape manufacturing, out-of-plane stiffness, strength, impact tolerance and ablation resistance recommend these materials.

Three dimensional(3D) braided composites were recognized as the most promising materials because of their low delamination tendency. Furthermore, the near-net-shape manufacturing, out-of-plane stiffness, strength, impact tolerance and ablation resistance recommend these materials.

Three dimensional(3D) braided composites were recognized as the most promising materials because of their low delamination tendency. Furthermore, the near-net-shape manufacturing, out-of-plane stiffness, strength, impact tolerance and ablation resistance recommend these materials.

Three dimensional(3D) braided composites were recognized as the most promising materials because of their low delamination tendency. Furthermore, the near-net-shape manufacturing, out-of-plane stiffness, strength, impact tolerance and ablation resistance recommend these materials.

- Specification

-

- Equipment type : TFB 3R 576

- Dimension (mm) : 3300(W) x 1600(L) x 3000(H)

- Braiding Type : Vertical Type

- X Axis Layer : 25 Layer

- Y Axis Layer : 23 Layer

- Braiding Carrier : 575SET

- Axial Yarn : 600EA

- Bobbin : 576EA

- Carrier Transfer : AIR CYL" ¢75-75ST

- Winding Motor : 3.7KW

- Winding Roller : Rubber Coating ¢250 x 500L

- Dust Collector : 3.7KW

- Bobbin Winder : Filment Winder

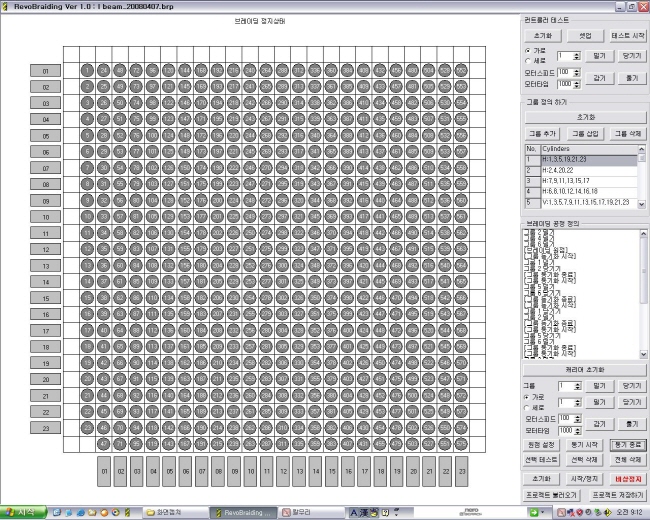

- Electric Control : PC Controller

- Control Card : 2 Axis Motion Controller

- Software : Revobraiding Version 1

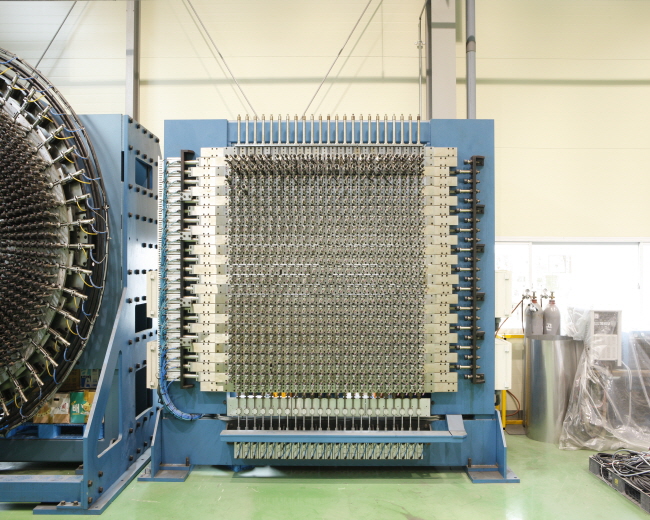

- Equipment Photo

-

- Equipment Photo

-

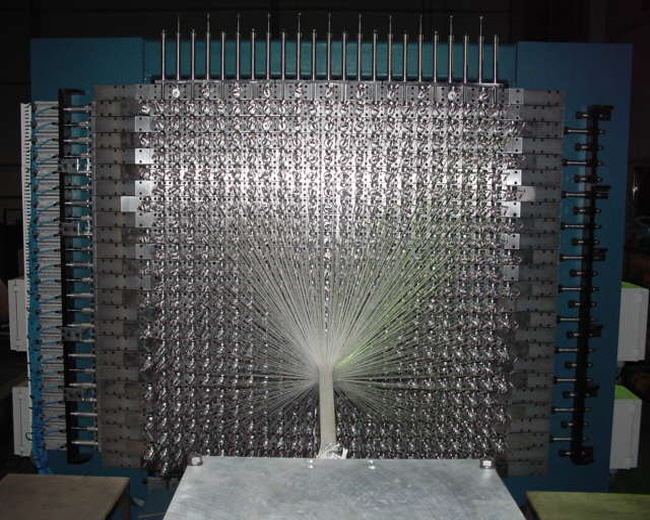

- Equipment Photo

-

- Equipment Photo

-

동영상