Automatic Machinery

Composite Equipment

5

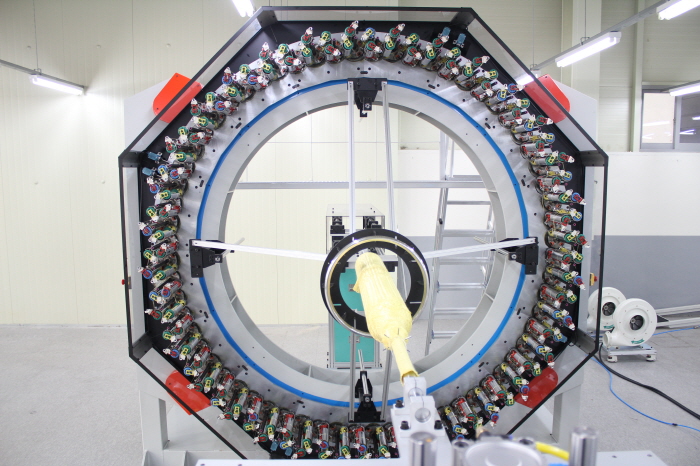

2D Over Braiding Machine for structural composite preform

The braided yarn forms a closed braid and is deposited on the mandrel. A “Preform” is generated. In addition, Braiding yarn supplies(carriers) has a patent on.

Overbraiding as a technique to produce structural preforms with braiding technique. With the overbraiding technique the continuous fibers are placed directly onto a pre-shaped core to take shape of the core. This is one of the reasons why the overbraiding technique has a low waste rate of 5 to 10%.

The braiding angles can be programmed between 15 and 80 degrees depending on the shape of the core, the number of braiding carriers and the width of the yarn. This gives a high degree of freedom in designing your component in an optimal matter and gives the opportunity for an extra weight reduction.

The core shape can be linear, curved or eccentric. After the overbraiding process the preform is braided into nett shape and can directly be used for the injection technique

The machine consists of a circular bed, an axial guiding tube, a large braider carrier together with formation, mandrel, and take-up units. The braider carrier moves around the axial fiber tubes according to a predetermined path to make ±bias orientation around the axial yarn. Thick structures can be produced by over-braiding on the mandrel. Complex structural parts can be made by cutting/stitching the fabrics

Overbraiding as a technique to produce structural preforms with braiding technique. With the overbraiding technique the continuous fibers are placed directly onto a pre-shaped core to take shape of the core. This is one of the reasons why the overbraiding technique has a low waste rate of 5 to 10%.

The braiding angles can be programmed between 15 and 80 degrees depending on the shape of the core, the number of braiding carriers and the width of the yarn. This gives a high degree of freedom in designing your component in an optimal matter and gives the opportunity for an extra weight reduction.

The core shape can be linear, curved or eccentric. After the overbraiding process the preform is braided into nett shape and can directly be used for the injection technique

The machine consists of a circular bed, an axial guiding tube, a large braider carrier together with formation, mandrel, and take-up units. The braider carrier moves around the axial fiber tubes according to a predetermined path to make ±bias orientation around the axial yarn. Thick structures can be produced by over-braiding on the mandrel. Complex structural parts can be made by cutting/stitching the fabrics

- Overbraiding technology

-

- Two groups of bobbins moving on concentric circles in opposite rotation direction

- Intermediate intertwining of the yarns

- Tubular braid is laid down on shaped mandrel

- Mandrel is moved through braiding eye

- Specification

-

- Equipment type : TFB 128

- Dimension(mm) : 3240(W) x 2100(L) x 3220(H)

- Braiding Carrier : Horizontal Type

- Axial Yarn : 64EA

- Bobbin Dimension : 55mm x 178mm / 350ccm

- Braiding Motor : 6KW

- Driving Gear : 64EA

- Speed(Horn gear r.p.m.) : max.120rpm

- Axial Yarn Creel : Inner Frame Attachment

- Mandrel : max. Φ350 x 1500mm

- Overbraiding Stroke : max.1500mm

- Overbraiding motor : Servomotor, 5Kw

- Overbraiding Speed : max.1000mm

- Overbraiding Pattern : max.10 Pattern

- Sleeve Winder : 3 st Rubber coated roller & motor

- Option : Bobbin winder 1set, Dust collector 1set, Bobbin spare - 128ea, Carrier spare - 2ea

- Equipment Photo

-

- Equipment Photo

-

- Equipment Photo

-