Automatic Machinery

Composite Equipment

5

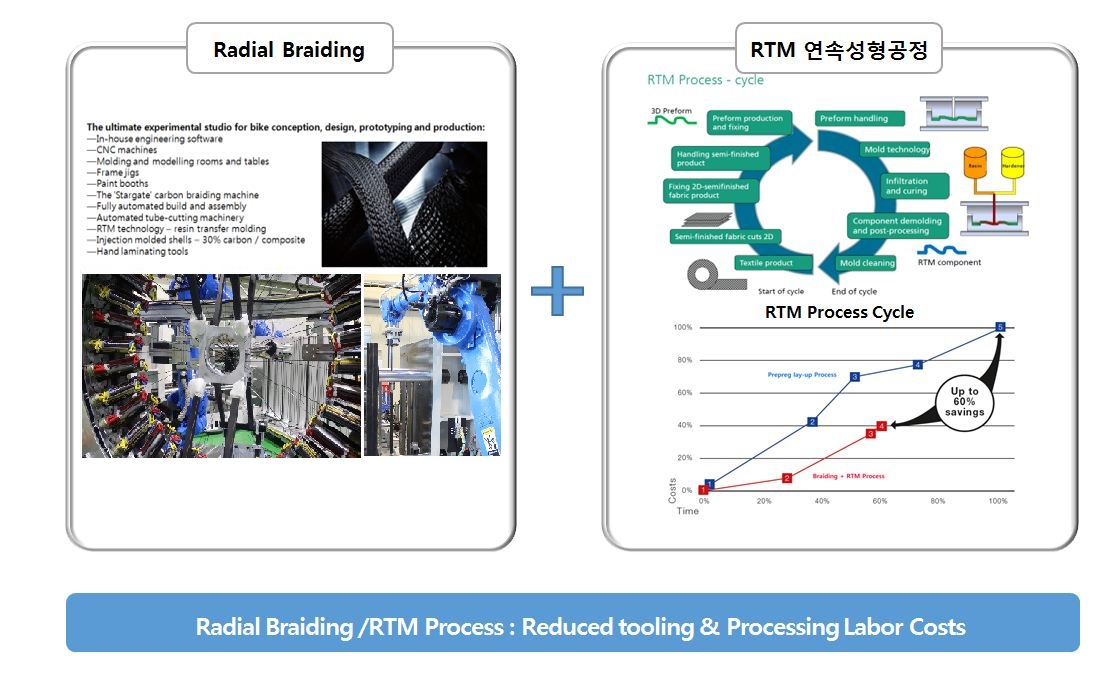

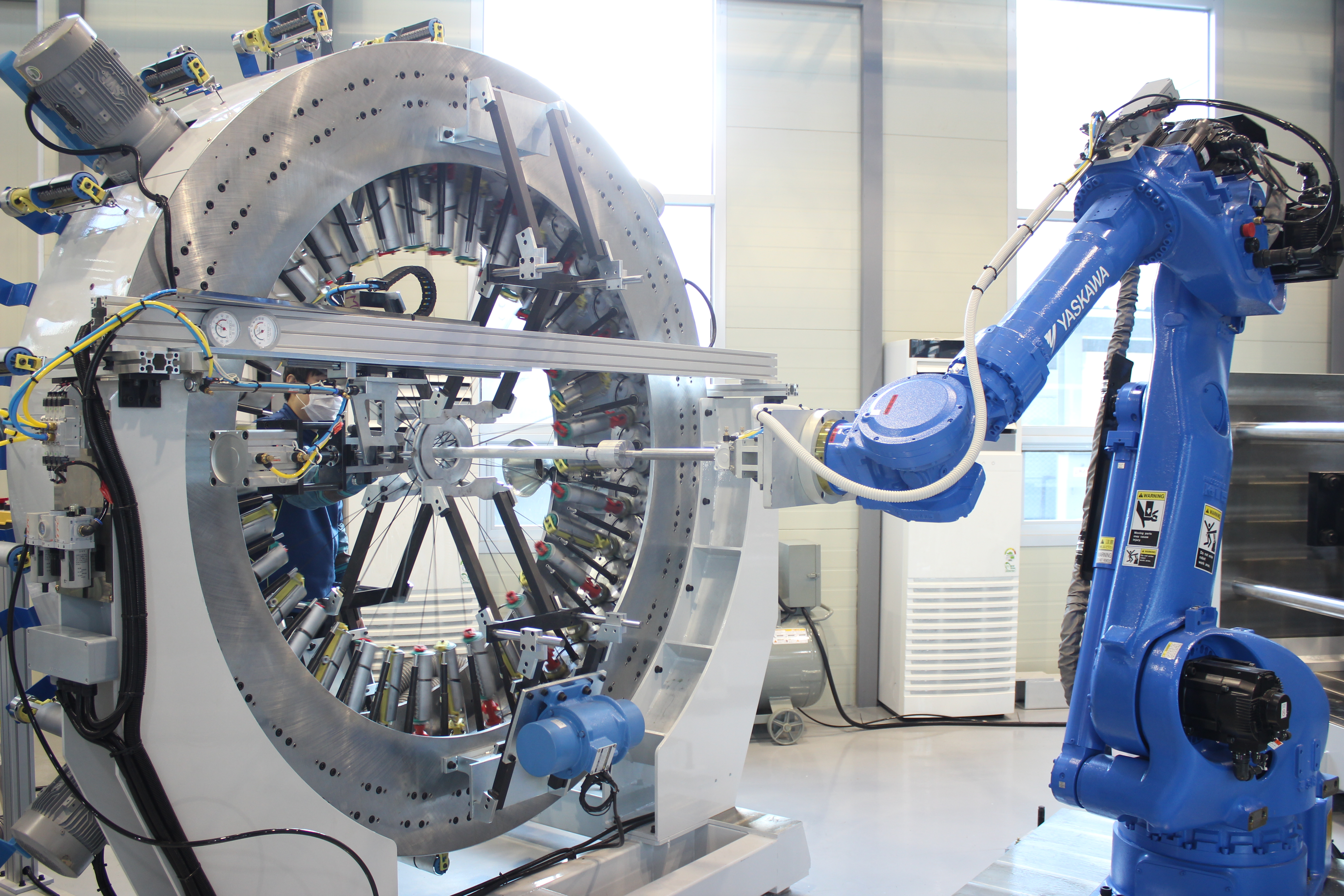

Radial Braiding Machine for advanced composite preform

The conventional orientation of bobbin carriers in both 2D and 3D braiding machines is either parallel with the machine axis or radially facing the center. However, braiding machines with bobbin carriers pointing radially inward to the braid point are known as radial braiding machines. Placing the track plate such that the bobbin carriers face the braid point decreases friction by minimizing tension variation and intra-yarn interaction and thus reduces filament damage. Atlantic Research Corporation developed a 3-D radial braiding machine. This design utilizes machine space effectively by placing bobbin carriers radially along braiding axis

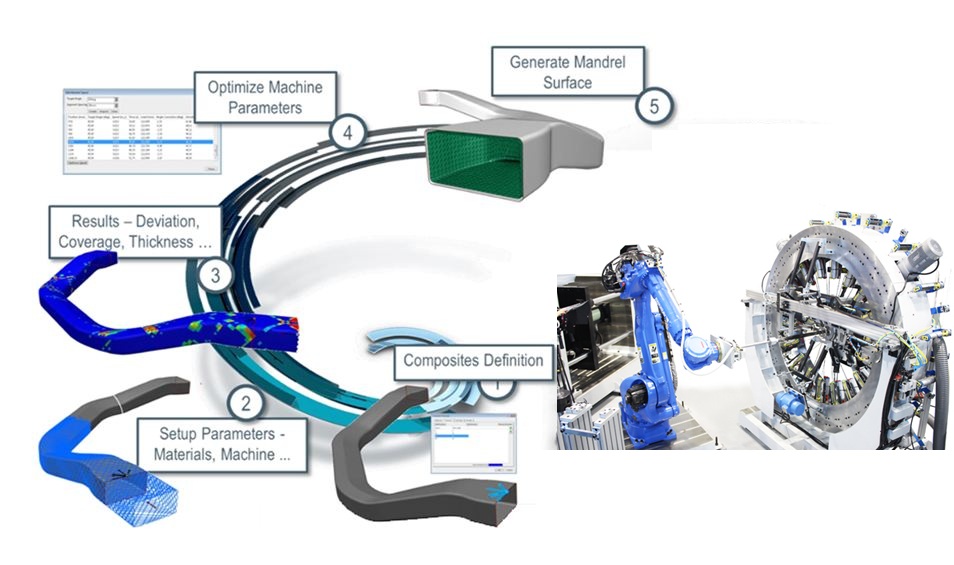

Radial braiding + Robot system

Radial braiding machine allows for manufacturing complex-shaped curved 3D woven structures. The unique design of this machine allows for 3 mode operation: manufacturing sleeve-shaped preforms; overbraiding a long part with variable diameter, over braiding curved boomerang-type parts.

Unlike conventional braiding equipment, which forms the braid in parallel to the bobbins and requires fiber movement that damages stiff, low elongation carbon fibers, T4L's radial braiding system for carbon fiber preforms reduces the span of fiber movement to only 0.10 inch/2.54 mm, and the fiber goes straight over the tensioning unit only once, not repeatedly, forming the braid at a 90° angle to the bobbins. This results in much less fiber breakage

Braiding interlaces three or more yarns together, forming a seamless textile preform over a mandrel. The textile’s interlocked fibers excel in torsional strength and impact resistance. Braided reinforcements also feature channels between the yarn bundles, which aid resin distribution during vacuum infusion and resin transfer molding

Radial braiding + Robot system

Radial braiding machine allows for manufacturing complex-shaped curved 3D woven structures. The unique design of this machine allows for 3 mode operation: manufacturing sleeve-shaped preforms; overbraiding a long part with variable diameter, over braiding curved boomerang-type parts.

Unlike conventional braiding equipment, which forms the braid in parallel to the bobbins and requires fiber movement that damages stiff, low elongation carbon fibers, T4L's radial braiding system for carbon fiber preforms reduces the span of fiber movement to only 0.10 inch/2.54 mm, and the fiber goes straight over the tensioning unit only once, not repeatedly, forming the braid at a 90° angle to the bobbins. This results in much less fiber breakage

Braiding interlaces three or more yarns together, forming a seamless textile preform over a mandrel. The textile’s interlocked fibers excel in torsional strength and impact resistance. Braided reinforcements also feature channels between the yarn bundles, which aid resin distribution during vacuum infusion and resin transfer molding

- Economic production of near-net shape textile preforms

-

- Possibility to insert 0°-Layers by taking-off without braiding

- Avoidance of roving on duration by realization of unidirectional (UD)-Braids

- Reproducible motion-sequences

- Automatable preforming process

- Machine control system is setup according to the following parameters

-

- Speed of horn gear rotation

- Braiding gauge

- Braiding diameter

- Speed of horn gear rotation is infinitely variable in the range of 50 rpm to 150 rpm. The machine is provided with a carrier positioning unit for easy bobbin exchange. Range of braiding roving angle to the axis relative to mandrel depending on machine model can vary from 25° to 85°, ignoring angle of wrap roving. All yarn guides are particularly suitable for carbon fiber yarns.

- Braiding of one layer and multi-layer preforms of round cross section with different diameter, thickness and length

-

- Manufacturing of one layer and multi-layer preforms cone shaped section of different diameter, thickness and length

- Manufacturing of hallow preforms of complex shape braiding method with preset parameters of mandrel surface area and angle of fiber placement relative to mandrel axis

- Manufacturing of multi-layer preform with rectangular section and cone shaped profile

- Radial braiding of carbon, woven or aramid fibers on a mandrel fixed by clamp system of manipulator of variable section and curved shape

- Multi-layer braiding on a mandrel due to multiple feed of a mandrel at braiding zone

- Braiding with preset parameters of mandrel surface area and of angle of fiber placement relatively to mandrel axis

- Braided sleevings with uniform section made of carbon fiber

- Braiding of flat triaxial fabrics

- Specification

-

- Equipment type : TFB 72

- Dimension(mm) : 2400(W) x 1600(L) x 2900(H)

- Type : Radial Type

- Braiding Carrier : 72EA

- Axial Yarn : 36EA

- Bobbin Dimension : 55mm x 178mm / 350ccm

- Braiding Motor : 6KW

- Driving Gear : 36EA

- Speed(Horn gear r.p.m.) : max.120rpm

- Axial Yarn Creel : Inner Frame Attachment

- Option : Winder 1set, Bobbin winder 1set, Dust collector 1set, Bobbin spare : 72ea, Carrier spare : 2ea

- Differentiation between existing and radial braiding

-

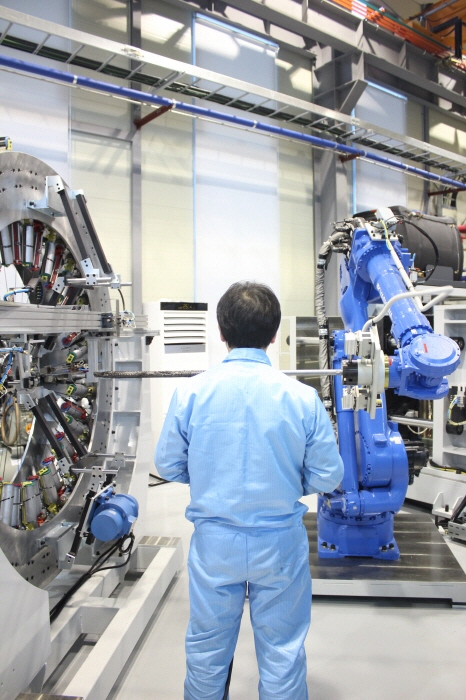

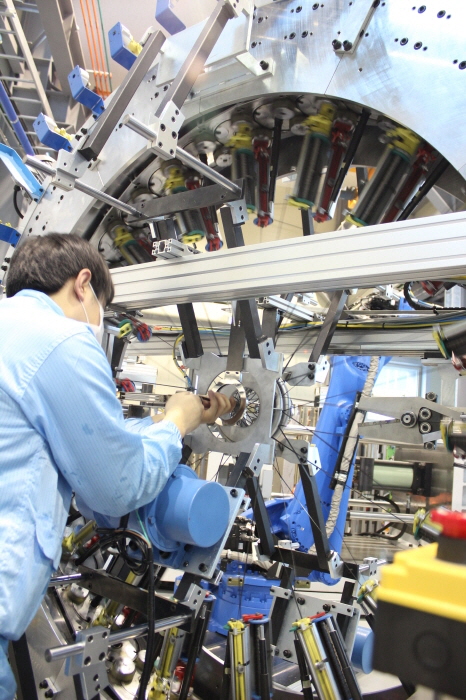

- Equipment Photo

-

- Equipment Photo

-

- Equipment Photo

-

- Equipment Photo

-

- Equipment Photo

-

동영상