Automatic Machinery

Composite Equipment

5

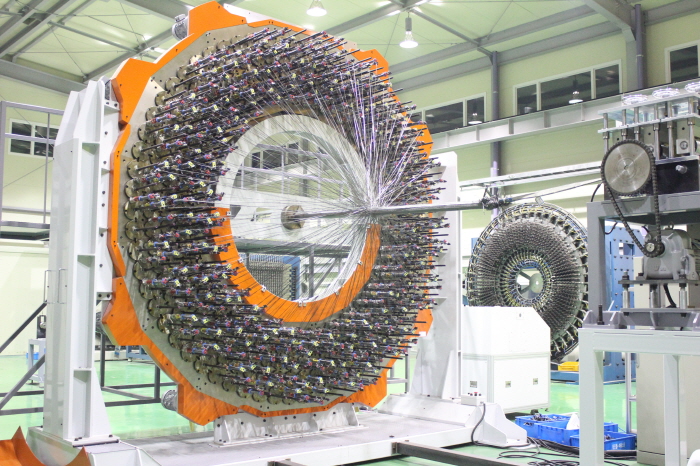

Layer to Layer 3D Interlock Braiding Machine for advanced composite preform

Layer to layer 3D interlock braiding machine designed in order to produce high performance composites parts has been developed for industrial purposes in aeronautic and automotive(specially propeller shaft)

this machine has a number of parallel braiding tracks around the circumference of the cylinder but the mechanism allows the transfer of yarns interlocking adjacent layers. the multi-layer interlock braid differs from both the 4-step braids in that the interlocking yarns are primarily in the plane of the structure and thus do not significantly reduce the in-plane properties of the preform.

the 4-step processes produce a greater degree of interlinking as the braiding yarns travel through the thickness of the preform, but therefore contribute less to the in-plane performance of the preform.

usually several separated layers have to be serially superimposed in order to form a multi-layer“2D braid” the problem of these multi-layer braids consist in the inter-laminar damage or its sensitivity to delamination. 3D braiding with interconnected layers overcomes this problem by intorductin reinforcing yarns of materials that transversely connect each to each the different layers during the process.

this machine has a number of parallel braiding tracks around the circumference of the cylinder but the mechanism allows the transfer of yarns interlocking adjacent layers. the multi-layer interlock braid differs from both the 4-step braids in that the interlocking yarns are primarily in the plane of the structure and thus do not significantly reduce the in-plane properties of the preform.

the 4-step processes produce a greater degree of interlinking as the braiding yarns travel through the thickness of the preform, but therefore contribute less to the in-plane performance of the preform.

usually several separated layers have to be serially superimposed in order to form a multi-layer“2D braid” the problem of these multi-layer braids consist in the inter-laminar damage or its sensitivity to delamination. 3D braiding with interconnected layers overcomes this problem by intorductin reinforcing yarns of materials that transversely connect each to each the different layers during the process.

- Specification

-

- Equipment type : TFB I320

- Dimension(mm) : 4500(W) x 2400(L) x 4200(H)

- Type : Horizontal Type

- Braiding Carrier : 320EA

- Axial Yarn : 320EA

- Bobbin Dimension : 42mm x 154mm / 174ccm

- Braiding Motor : 12KW

- Driving Gear : 320EA

- Speed(Horn gear r.p.m.) : max.120rpm

- Axial Yarn Creel : Inner Frame Attachment

- Option : Winder 1set, Bobbin winder 1set, Dust collector 1set, Bobbin spare - 320ea, Carrier spare - 6ea

- Equipment Photo

-

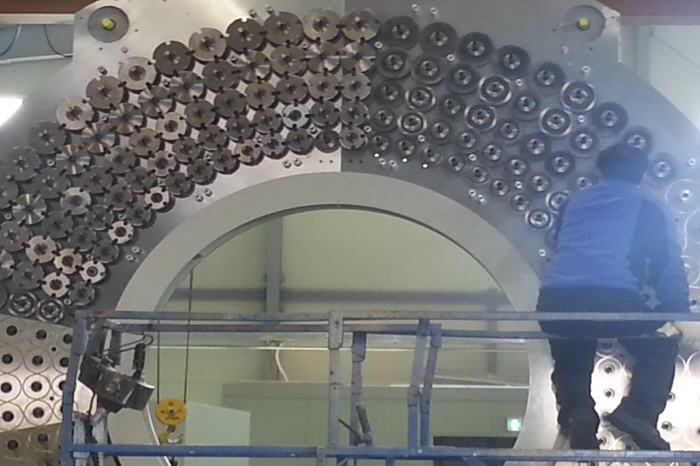

- Equipment Photo

-

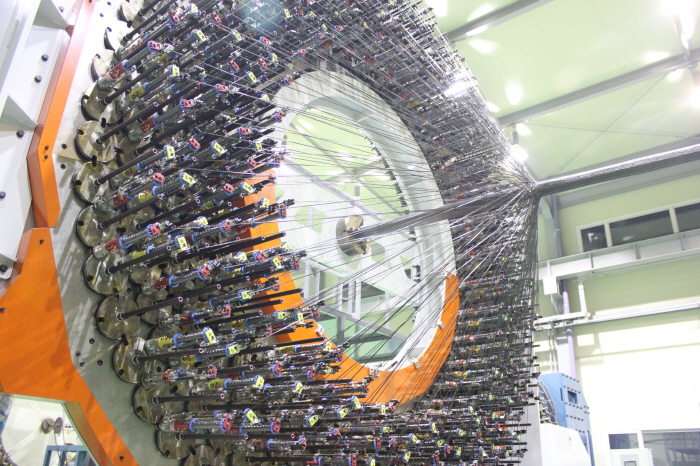

- Equipment Photo

-

- Equipment Photo

-

동영상