Automatic Machinery

Composite Equipment

8

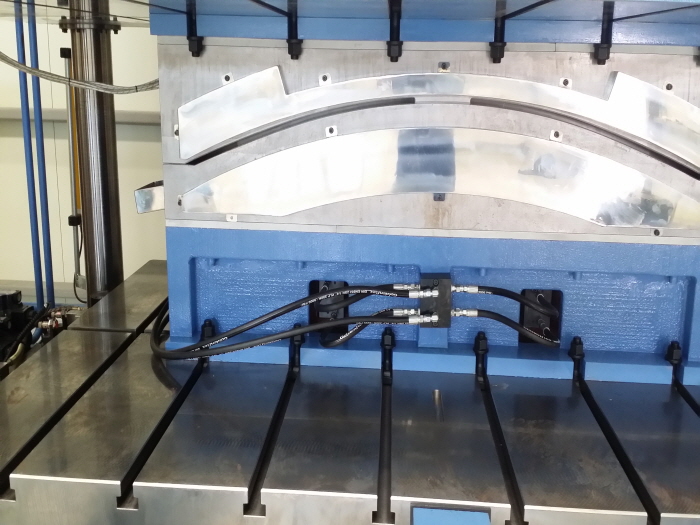

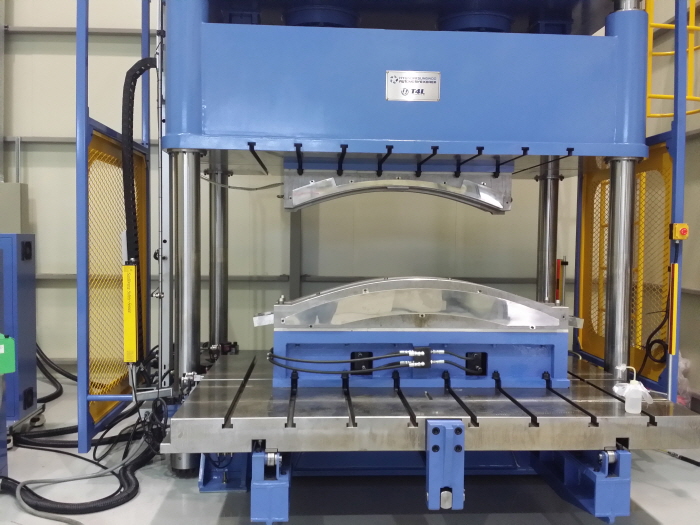

Hot Press Machine for compression moulding

Designed with special isolating devices to prevent wearing of the heat plate and the in/out-mold plate.

- Characteristic

-

- Front ejector: Designed using double-layer oil-less bearings, protected with a dust seal.

- Monitoring design: Allow overall monitoring on machine actions, pressure and flow rate, and warning messages and records.

- Hydraulic circuit design : Fully proportional hydraulic system, pressure and speeds can be easily adjusted.

- Electrical control system

-

- Precise temperature control is achieved using PID calculation, temperature can be adjusted by connecting the man-machine interface.

- The module saving function includes temperature, pressure/ flow rate, time, injection position, upper/lower position, and function settings

- Heating system: uses SSR solid relay with fast heat-up without exceeding the limit. Mold calibration: available with slow mode calibration.

- Equipment Photo

-

- Equipment Photo

-

- Equipment Photo

-