Automatic Machinery

Composite Equipment

7

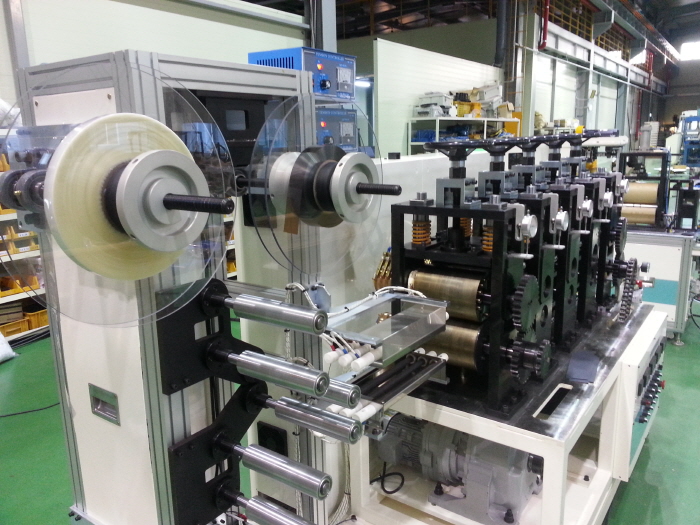

Tow prepreg machine[Thermoplastic/Lamination]

In the continuous production of the UD prepregs, thermoplastic films are applied on both sides of one layer of UD fibres with a defined area weight and hence the reinforcement is impregnated with thermoplastic melt.

- Prepreg Machine for processing Unidirectional fibers and Technical Fabrics

-

- Fully automated controls package

- Multi-Fiber Spreading System

- Individual drives on each roll set providing better process control

- 3~5 precision compaction roll sets with heat distribution system

- Proprietary Bed-Plate Construction

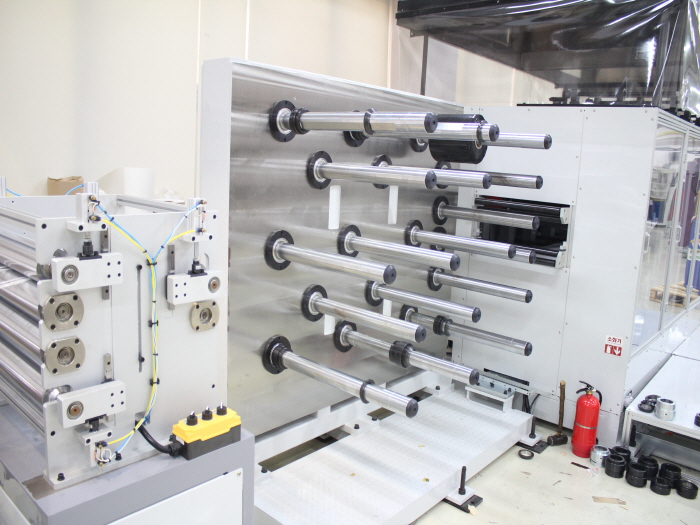

- Top and Bottom Paper Rewind and Let-offs

- Proprietary Slitting Device Construction

- Available in 400~1000mm width capacity

- Highly reliable and easy to operate

- Specification

-

- Prepreg Width : max. 400 ~ 1000㎜

- Driving Speed : max. 3m/min.

- Thermoplastic Resin Impregnation : Hotmelt type Film Lamination

- FAW Control : 75~400 ± 5g/㎡

- R/C Control : 30~50 ± 2%

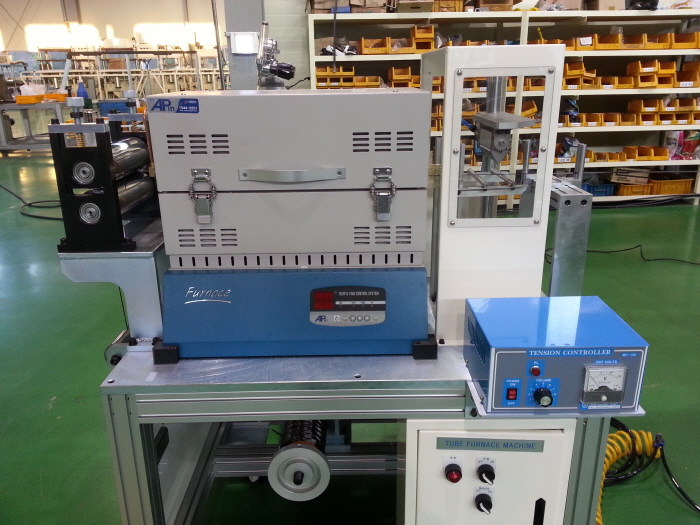

- Heating Temp : max. 400℃

- Cooling Temp : 30~50℃

- Compressing & Calendering roller : 5set Heating roller

- Resin Film Thickness : 25~100㎛

- Dimension : 13000mm(W) x 2400mm(D) x 1900mm(H)

- Electric control : PLC Software + Touch Screen

- Electric capacity : 60Hz, 120KW

- Option : Roving Creel, Film Creel, Slitting/Winding), Drum Winding

- Equipment Photo

-

- Equipment Photo

-

- Equipment Photo

-

- Equipment Photo

-